Description

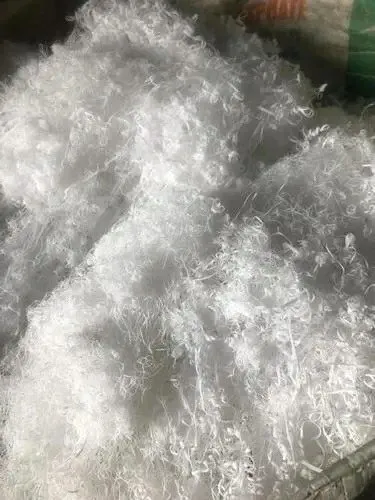

PTFE scrap refers to discarded or leftover Polytetrafluoroethylene (PTFE) material from manufacturing, machining, or post-consumer waste. PTFE is known for its high chemical resistance, non-stick properties, and excellent temperature resistance, making it valuable even as scrap for recycling or repurposing.

Types of PTFE Scrap:

✔ Virgin PTFE Scrap – Pure PTFE material without fillers, often from manufacturing cut-offs.

✔ Filled PTFE Scrap – Contains additives like glass, carbon, or bronze for enhanced properties.

✔ PTFE Powder or Shavings – Fine particles from machining or grinding.

✔ Used PTFE Components – Worn-out gaskets, seals, bushings, or coatings.

Recycling & Reuse Options:

♻ Reprocessing into New Products – Can be re-molded or sintered into new PTFE parts.

♻ Mechanical Grinding – Processed into PTFE powder for use as an additive in coatings or lubricants.

♻ Industrial Applications – Reused in non-critical sealing, insulation, or friction-reducing applications.

♻ Chemical Recycling – Broken down into reusable fluoropolymer compounds.

Common Applications for Recycled PTFE:

🏗 Construction & Sealing: Reused in gaskets, O-rings, and sealing components.

🚗 Automotive & Aerospace: Applied in non-critical wear-resistant parts.

⚙ Industrial Coatings & Lubricants: Used in anti-friction applications.

🔬 Laboratory & Chemical Processing: Maintains chemical-resistant properties for labware and tubing.